Filler masterbatch

No carrier talc filled masterbatch

Product specification

Appearance: white cylindrical particles

Physical properties: white degree of 96% or more; Moisture 0.3% or less; Loose the proportion of 0.5% or less; Silicon dioxide 60% or higher; Magnesium oxide 30% or higher

Product features:

1, it has good compatibility with plastic, dispersed evenly in the products, can keep the original products of basic mechanical properties, while the impact strength, size stability index increased.

2, this product has basic plastic particle size and its perfect granule shape and easy to use, add a large amount, obvious reinforcing effect, improve the strength of plastic products, no dust pollution, reduce the cost.

3, the product after testing is a non-toxic products.

4, the product with high whiteness, high fineness, easy dispersion, and the advantages of good intermiscibility with other pigments.

5, adopt a new surface activation treatment technology (new comminution technology and efficient coupling agent surface activation treatment). The secondary granulation process middle is not the material, the production efficiency more than doubled.

6, filling quantity is big, mixed with resin, accurate measurement good evenly dispersed in the resin.

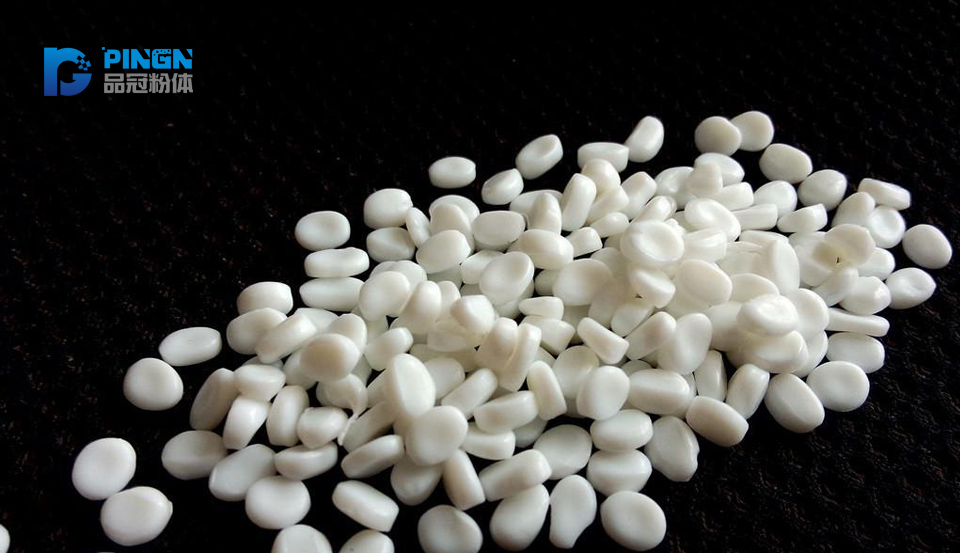

Carrier filler masterbatch

New highly filled polyolefin masterbatch is USES the overseas advanced technology formula and granulation production control system, developed a new type of high-tech product, its core is through the granulation technology, distribute the modified powder granulation, the masterbatch in polymer matrix in a specific structure to quickly spread, masterbatch stable microstructure and mechanical properties, good processing rheological properties, greatly reduces the production cost and meet the needs of industrial production.

Product features:

This product is environmental protection, no dust, non-toxic, tasteless, conform to the requirements of the state environmental protection technology.

Injection molding products, can be a one-time joining, need not repeat granulaCarrier filler masterbatch

New highly filled polyolefin masterbatch is USES the overseas advanced technology formula and granulation production control system, developed a new type of high-tech product, its core is through the granulation technology, distribute the modified powder granulation, the masterbatch in polymer matrix in a specific structure to quickly spread, masterbatch stable microstructure and mechanical properties, good processing rheological properties, greatly reduces the production cost and meet the needs of industrial production.

Product features:

This product is environmental protection, no dust, non-toxic, tasteless, conform to the requirements of the state environmental protection technology.

Injection molding products, can be a one-time joining, need not repeat granulation, reduce the processing cost.

Enhance product hardness, rigidity, compressive strength abrasion resistance and reducing product shrinkage.

Reduce wear and tear of equipment, reduce the products in the color change when cleaning screw with shoes, improve production efficiency.

Basic and plastic particles size, perfect granule shape and high whiteness and good transparency.

Product specifications:

Appearance: white particles, colour and lustre is uniform particle size: 2-3 mm loose weight: 1.80 g/cm3

Water: < 0.4% melt flow rate: adjustable according to customer requirements

Product use

Products are widely used in injection molding, blow bottles, plastic forks and knives, snack box, pipe, sheet, hollow plate, electrical housing, packing belt, woven bags, garbage bags, shopping bags, non-woven fabrics, striped cloth, stretch film, etc.

If you want to get more detailed information, please contact us.